copyright© 2014 Piscinadimare.it S.a.s.

|

Chlorine Generators

The Piscinadimare.it Chlorination Plant covers a diverse range of units, with sodium hypochlorite output varying from 50 grams to suit small commercial pools to the large production modules delivering 2 kilograms per hour. Unlike other hypochlorite generators, our system does not need any hypochlorite solution intermediate storage: the produced hypochlorite solution is dosed in the process on a continuous basis and rate of production is directly controlled according to instantaneous process needs.Not having any intermediate storage tank allows to avoid the problem of H2 developing from solution into tank, (and related problems of explosion when this gas is present in specific percentage in air). Moreover there is no possibility of hypochlorite solution decay due to storage, that may lead to loss of oxidising power and to presence of undesired substances in solution. Process control carried out on a continuous basis allows to produce only the hypochlorite quantity instantaneously required by the process, so avoiding too high dosages that lead to increase of costs and to the need to remove the excess of chlorine before discharging the water.

|

ReChlorSystem

Self cleaning pool chlorinators with inbuilt (pH, Redox, chlorine indirect readout) for residential swimming pools

MAIN FEATURES

1) Inbuilt pH control and readout with peristaltic 4 lt./Hr. pump

2) Inbuilt Orp control and readout

3) Salinity alarms

4) Chlorine output proportional (P.I.D.) from Redox readout

6) Low acid level in the tank alarm

7) Inbuilt Flow switch

8) 4-20 mA input for external analyzer

9) Fully programmable software

Automatic ramp of slope of the tension/current adjustable;

- Electronic limitation of current limitation device at maximum value of the rectifier in the case of overload or short-circuit, which reduces voltage to lower values.

- linear adjustment of voltage or current from 5 to 100% of power, by control panel, maintaining the preselected value stabilized with a percentage of +/- 1%.

- Feeding of the auxiliary circuits and driving of regulation through safety transformer to 24V ac in class F normative compliant CEI EN 61558 2-6.

- Transformer of power and secondary to IGBT with bridge whole connection with impedance of leveling, largely norms dimension CEI EN 61558 2-6 with class of isolation H and class of temperature F; adjustment unit with thyristors, connected to the secondary of the transformer, adjusted by highly reliable electronic actuation.

Sodium Hypochlorite Plant with new PMX® diaphragm

Thanks to the Polyramix diaphragm, we developed an innovative vertical, modular electrolyser, based on the well known ELM membrane electrolyser basis, that finally permit the sodium hypochlorite production with a simple, reliable and user friendly configuration. The result is the possibility to produce on site small-medium (from 300 to 20.000 l/day) quantities of high strength sodium hypochlorite (active chlorine concentration from 100 to 145 g/l)!! Before, such results was possible to be achieved only adopting the membrane technology, with all the limitations and difficulties due to this delicate media.

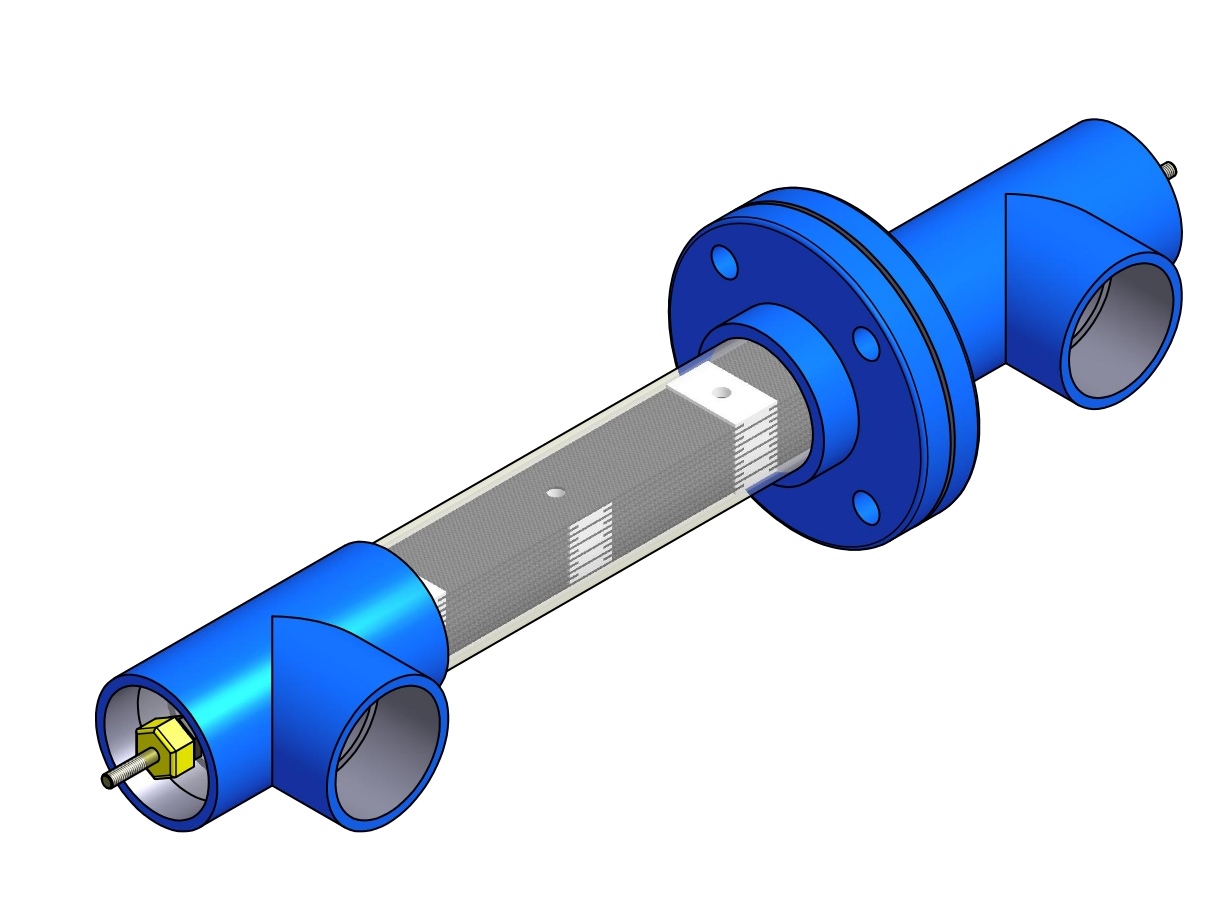

On-Site Chlorinator

Electrochlorination is the process of producing sodium hypochlorite by running an electric current through salt water. It is used to disinfect water to make it safe for human usage, such as for drinking water or spas/swimming pools, where contaminants from people and the environment are constantly introduced, or as practical system to eliminate the fouling clorazione acqua di marein plants using seawater.

Our seawater electrochlorination systems use a simple and straight forward electrochlorination process, combining three common consumables (salt, water and electricity) to generate a disinfecting agent. Seawater electrochlorination eliminates the storage, handling and purchase of hazardous chemicals